BKS-TH600automatic lamination machine

一. Equipment description:

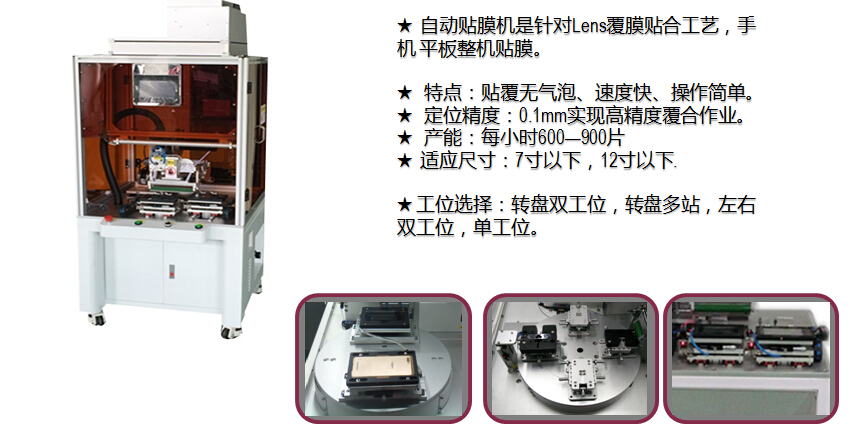

Bks-th600 automatic laminating machine is for Lens film laminating process, realizing semi-automatic production deft and light, desktop machine. Concentrated the large equipment of draping, with no bubble, speed and other characteristics, join the current mainstream CNC CNC machining center, the control principle of so as to achieve combined with high precision, fast draping, no bubble, the operation is simple, portable, easy to manage, and strong practicability, etc.

Bks-th600 automatic lamination machine is used to construct XY mobile platform with two high precision linear modules, and the positioning accuracy reaches 0.01mm to achieve high precision overwork. In addition, the original advantages have been added to the interchangeable function, which increases the speed of the original film cover by 40%, which can achieve the goal of non-interference between man and machine in safe operation.

二.Technical standards

1. Capacity: 10-12 pieces/min (depending on the product size)

2. Accuracy: test XY 2, plus or minus 0.1mm (considered to be 0), smooth and flat, smooth and smooth on the edge of the film

3. Bubbles: there is no bubble in the protective film.

4. Stability: 24 hours continuous working without exception

5. Maximum film size: 145x155mm (adjustable according to customer requirements)

6. Air pressure: 0.5mpa (with adjustable air valve)

7. Calibration method: XY axis correction mode

8. Power supply: AC220V 50HZ 10A

9. Vulnerable parts: rubber rollers

10. Feeding and treating with air float platform

三. Major improvements

1. Strengthen the strength of linear module (improve operation stability)

2. Increasing tilting suction head (which can improve the problem of bonding and white printing)

3. The stripping plate increases the negative pressure adsorption section (which can improve the lateral deviation of the membrane)

4. Change the suction driving form (strengthen the stability of suction head)

5. Change of film driving form (reducing film error)

6. Increase cycle rotation swing set plate (improve the working efficiency of workers' placement time)

7. Effectively solved the security risks and thus reached the human-computer interaction.

四. Equipment specification parameters:

|

control |

master program |

Panasonic |

|

man-machine interface |

WENVIEW 7〞Color touch screen |

|

|

Servo control |

Panasonic |

|

|

Feeding brake system |

In guangzhou hongtai |

|

|

False protection |

Bidirectional interlock design of machine software and hardware |

|

|

Waves are stable |

EMI filter |

|

|

Power protection |

20A Reset leakage switch |

|

|

power supply |

DC24V(Built-in power supply) |

|

|

Electrical, structural configuration |

Positioning detection |

KEYENCE |

|

thickness of the test |

LRD |

|

|

motor |

||

|

light source |

Dual LED light source |

|

|

Head cylinder |

Japan SMC cylinder |

|

|

Head guide rail |

Japan THK high precision guide rail |

|

|

Pressure regulation |

Japan SMC precision pressure control valve |

|

|

Pressure indicator |

Japanese SMC precision digital display table |

|

|

vacuum |

Japan SMC vacuum generator |

|

|

Solenoid valve |

Japan SMC |

|

|

Air filter |

Japanese SMC water distributor |

|

|

Parameter input |

Chinese interface |

|

|

Attached with a precision |

The test is based on the test of XY |

|

|

Air pressure control |

0.1MPa~0.8 MPa |

|

|

Pressure range |

10Kgf~88Kgf |

|

|

Precision of pressure |

±0.1KG |

|

|

Product specification |

145x155mm |

|

|

Fixed mode of product |

Vacuum adsorption |

|

|

Height of homework |

750MM |

|

|

Frame structure |

Rectangular tube welding |

|

|

Fixture materials |

teflon |

|

|

Table/pressure structure |

45# steel heat treatment |

|

|

Shell sealing plate |

2 mm plate of the lacquer that bake |

|

|

Field to beg |

The power supply |

AC220V 50Hz±10% |

|

Maximum current |

10A 2000W |

|

|

The supply air |

0.4~1Mpa(Dry air) |

|

|

Tracheal specifications |

¢8MM |

|

|

The working environment |

Applicable to standard workshop |

|

|

Equipment specification |

External dimension |

Long 1350MM wide and 750mm high in 1960 MM (including FFU360MM) |

|

The total weight |

about 350KG |

|

|

Equipment features |

vertical |

|

|

Platform work mode |

Rotary table workbench |

|

|

operator |

1 person |

|

|

protection |

Job security |

Dual key start operation |

|

The action to protect |

Software action interlocks |

|

|

Random accessories |

The trachea |

10M/quick joint 1 set |

|

Attached with a wheel |

1 (based on product customization, installed on the machine before delivery) |

|

|

jig |

1 set of 2 (according to the product order, installed before the factory is installed) |

|

|

machine tool |

1 set |

|

|

Job instructions |

1 |

| Prev:None | Next:BKS-THSmall size hard to hard line |